Busbar Processing Machine

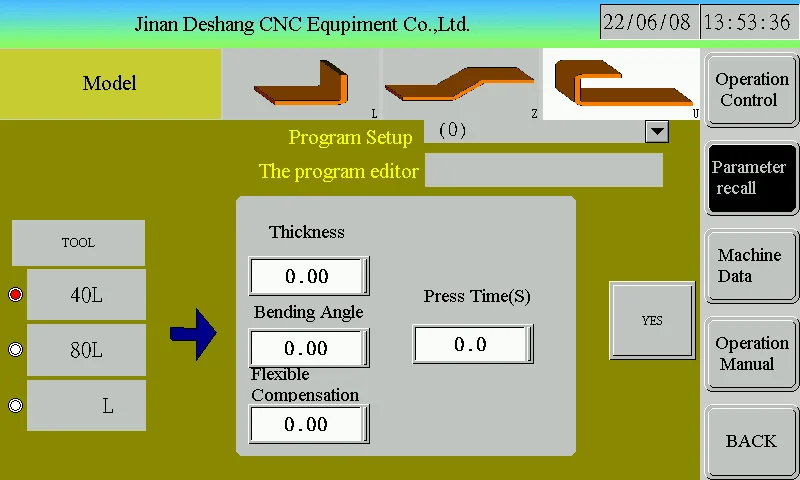

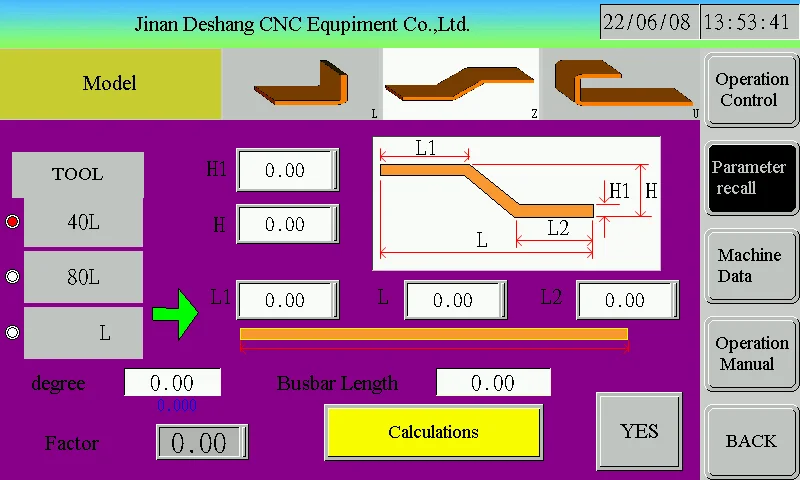

The busbar bending machine can achieve bidirectional positioning of the X-axis and Y-axis. During the work process, the operator does not need to draw cross lines or punch foreign punches, which improves work efficiency and the accuracy of stamping positioning pins, making production and processing positioning more accurate. The marking is accurate, intuitive, practical, stable, and easy to operate, allowing for arbitrary fine-tuning of waste laser lines in three-dimensional space.

Description

Function:

* The busbar machine is designed to cater the requirement of bus bar preparation & almost all operations are

* This is a highly productive machine suiting to growing demand of Industries.

* The busbar banding cutting and punching machine is equipped with three different & independent stations

* International quality hydraulic & electrical components ensure maintenance free long life.

High Quality 3 In 1 Hydraulic Busbar Processing Machine

Hot Tags: Busbar Processing Machine, suppliers, manufacturers, first price, OEM factory, for sale, Busbar Punching Bending Cutting Machine, Copper Busbar Cutting Machine, CNC Busbar Cutting Machine, Copper Busbar Punching Machine, Busbar Leveling Machine, Busbar Cutting Punching and Bending Machine

Send Inquiry

You Might Also Like